Line arrester for transmission line

Flashover

by lightening is the major factor of line faults in transmission systems. Line

arrester would be much more effective solution to reduce the fault on overhead

transmission lines, compared with another countermeasures such as differential

insulation system, implementation of multiple shielding wires or reduction of

tower footing resistance.

In

Japan, more than 50,000 sets of Zinc oxide line aresters, which interrupt

power frequency follow current within 1/2 cycle, have been installed on the

important lines in higher isoklonic areas since 1980fs, and their

performance has been proved.

Basic

design of line arrester

For

overhead transmission lines, reliability of insulation performance as well as

free of maintenance is especially required. Further more, successful re-close

operation must be assured if the arrester was failed by unexpected larger

magnitude of lightening surge. From this point of view, external series gap

type arrester has been used in Japan. As shown in Fig.1, the polymer arrester

unit is mounted with the external series gap. The gap is designed to withstand

switching surge and power frequency over voltage in the system. Since the

arrester unit is isolated from high voltage, no deterioration of arrester unit

due to continuous energizing is considered.

Fig.1 External series gap type line arrester

Compact type line arrester

Based

on the above proven technology, more compact type of line arrester

was developed. Because of compactness and lightweight, it can be installed

easily like arcing horn for insulator string. Though it is designed to

withstand smaller lightening impulse current than that of the present design,

it still has enough performance to prevent back flashover when used in

shielded systems. That is, good cost performance is expected including

installation work. Technical data of the compact type line arrester is shown

in Table 1.

Using

EMTP (Electro-Magnetic Transient Program) analysis, the expected frequencies

of lightening fault before and after installation of line arrester were

compared. As shown in the bottom column of Table 1, the compact type has

enough lightening current discharge capacity.

Photo 1 69kV Compact type line arrester

Table 1 Technical data

|

Item |

Compact type |

Present type |

|

System voltage |

33 to 161kV |

33 to 500kV |

|

Max. discharge current (4/10Ês wave) |

30kA |

100kA |

|

Over duty operation |

Pressure relief |

|

|

Housing material |

Silicon rubber |

Silicon or EP rubber |

|

Mass of arrester unit (for 69kV system) |

Approx. 2kg |

Approx. 10kg |

|

Effect to prevent tripping by lightening |

Approx. 95 % |

> 99 % |

By Engineering Department, Insulator Division

NGK

INSULATORS, LTD.

1155

Tagami, Futaebori, Komaki 485-8566, Japan.

Tel:+81-568-76-7247, Fax:+81-568-76-7261

http://www.ngk.co.jp

Until today porcelain has been used as insulating materials outdoors due to the successful results obtained for many years.

|

Photo.1. 66kV Oihama line No.1 tower (Outdoor termination with composite insulator) by Tokui Yonemura,Furukawa Electric Co.,Ltd and Takeshi Goto, The Tokyo Electric Power Company, Japan

During recent 20 years, with the improvement of the

characteristic of the composite insulation materials including silicone

rubber, the use of composite insulators, which have light weight, high

mechanical strength and contamination resistant characteristics with

phase-to-phase spacer and tension insulator, has become popularized.

Furthermore, in recent years the application of composite insulators is

advancing also in bushing.

Along with a FRP cylinder that has superior mechanical strength

surrounded by silicone rubber cover and shade with excellent electric

performance, a composite insulator has a structure with the metal fittings

helping to mount it firmly on FRP at both sides.

In comparison with porcelain insulators, composite insulators have a

number of advantages in contamination resistance, safety, workability and

cost. Particularly when the

termination is to be mounted on a steel tower, composite insulators have

become a dominant choice for such a use due to such characteristics as safety,

workability, etc.

Beginning in 1996, Furukawa Electric Co.,Ltd

with the Tokyo Electric Power carried out development and research on

66kV and 154kV composite insulator terminations for tower-mounted branch line.

|

The 66kV composite

insulator terminations were used for branching

on the tower of Oihama line of Tokyo Electric Power Co. in the year, 2000.

This marked the first application of composite insulator termination in Japan.

Development of the 154kV class composite insulator termination has

substantially been completed, and the composite insulator termination is at

the stage where practical application is possible.

Accredited Testing Laboratory

|

By High Voltage and High Power Testing Laboratory, Toshiba Corporation, 2-1

Ukishima-cho, Kawasaki-ku, Kawasaki, 210-0862 JAPAN,

http://www2.toshiba.co.jp/f-ene/hvhp

@

TOSHIBA Testing Laboratory is the first accredited

High Voltage and High Power Testing Laboratory in Japan. TOSHIBA quality

systems have been officially accredited based on ISO/IEC guide25 by the Japan

Accreditation Board for Conformity Assessment (JAB) in 1999. Moreover, TOSHIBA

is a member of the Short-circuit Testing Liaison, the global forum for

international collaboration between organizations.

High

voltage tests and high power tests are carried out in accordance with IEC, JEC,

ANSI, JEC and any national standards. After successful results of the tests,

TOSHIBA will issue a Test Certificate for the tested objects.

TOSHIBA

have the high voltage reference divider (rated voltage 500kV) made by HAEFELY.

It is traceable to PTB (Physikalsch-Technische Bundesanstalt) in Germany. Our

main measuring system is fully calibrated with its reference system according

to standardized IEC60060-2.

Typical Test Products

The

most products for power systems can be tested in the TOSHIBA Testing

Laboratory.

Typical test products are:

Circuit

breaker

Disconnecting switch

Earthing

switch

Transformer

Current

Transformer Potential

transformer

Reactor

Surge arrester

Bushing

Bus

Cable

load switch

Resister

Terminal

Relay

Fuse

Semi-conductor

Switchboard

DC

circuit breaker

On load tap changer

Test Facilities

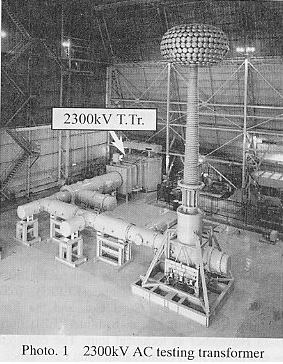

High voltage testing Laboratory has a 2300kV AC testing

transformer made by TOSHIBA shown Photo. 1, 6000kV impulse generator and

2000kV DC generator. High power testing laboratory has 6600MVA(0.06s after

short circuit) short circuit generator made by TOSHIBA shown Photo. 2 and

5.4MJ capacitor bank for synthetic breaking@test.@Tests in the class of 1000kV equipment are carried out.

These facilities perform the maximum world level tests.

Test

and Analysis Services

Not only test service of high voltage and high power for

distribution system or transmission system, but also many analysis services

can be provided. For example, transients analysis, arc phenomena analysis,

three dimensional electric field analysis, etc. are available.

We

welcome inquiries about electrical tests and technical assistance, and can

comply with your requirements.